Crankshafts Manufacturers: The Backbone of Diesel Engine Performance

The automotive industry relies heavily on its components for efficiency and reliability. Among these components, crankshafts represent a crucial element, particularly in the realm of diesel engines. This article explores the significance of crankshafts manufacturers and their pivotal role in ensuring optimal engine performance.

Understanding the Crankshaft's Role in Diesel Engines

A crankshaft is a mechanical component that converts the linear motion of the pistons into rotational motion, enabling the vehicle to move. In diesel engines, this conversion is vital for delivering the power necessary for various applications, from heavy-duty trucks to industrial machinery.

Key Functions of the Crankshaft

- Power Generation: It transforms the energy produced from fuel combustion into usable energy.

- Vibration Dampening: A well-designed crankshaft helps minimize engine vibrations, leading to smoother operation.

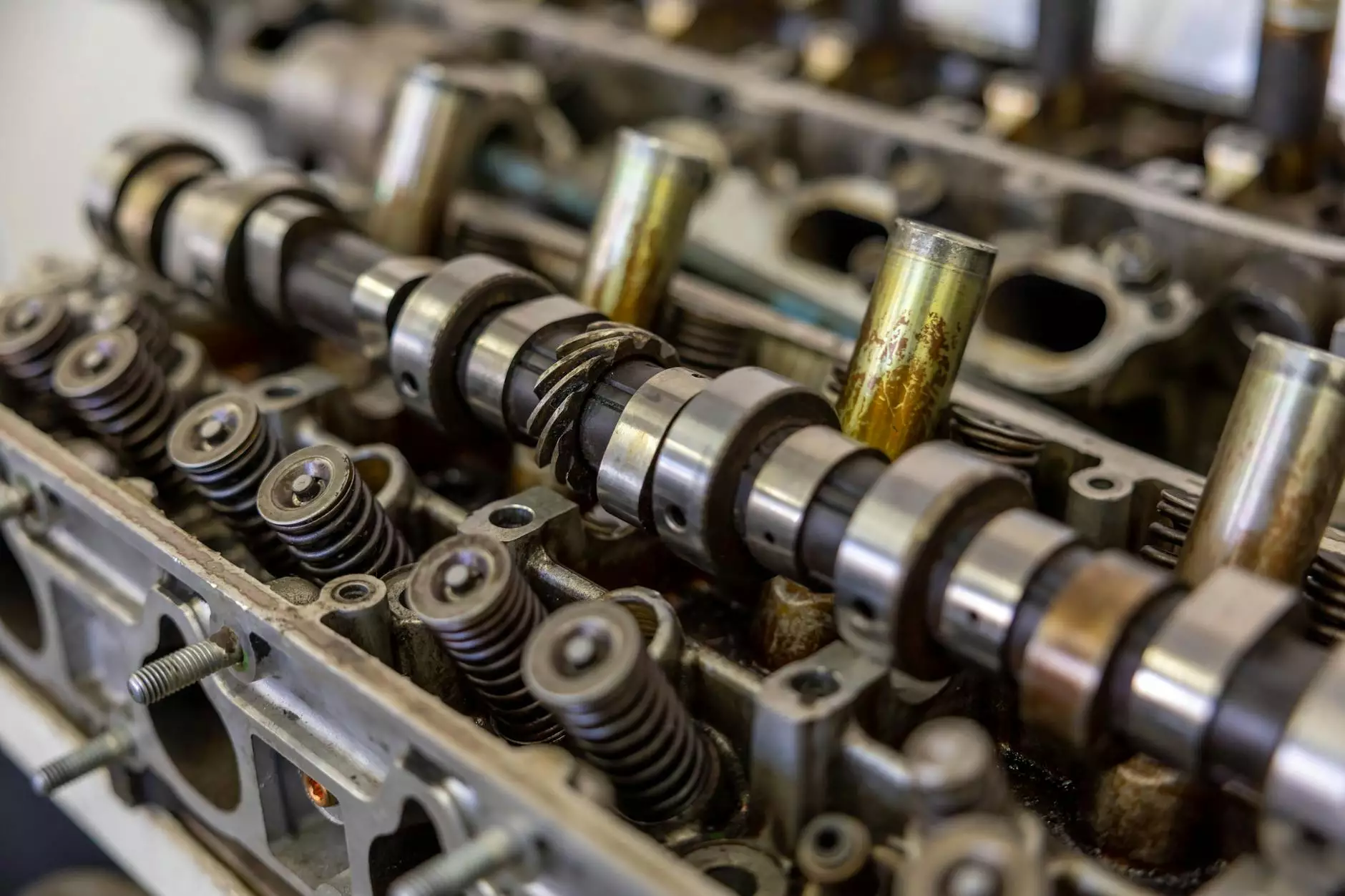

- Connecting Components: The crankshaft works in tandem with other components, such as the camshaft and flywheel, to ensure coordinated engine performance.

The Manufacturing Process of Crankshafts

The process of manufacturing crankshafts is intricate and requires precision engineering. Here’s a detailed look at the steps involved in producing quality crankshafts.

1. Material Selection

Crankshafts are typically made from high-strength materials such as forged steel, cast iron, or aluminum alloys. Material selection is crucial as it directly influences the durability and performance of the crankshaft.

2. Forging and Casting

Once the material is selected, the next step involves either forging or casting the crankshaft. Forging offers superior strength and resistance to fatigue, while casting can provide complex shapes at lower costs. Each method has its advantages depending on the intended application of the crankshaft.

3. Machining

After the initial shaping, crankshafts undergo precise machining processes to achieve the necessary tolerances and surface finishes. This includes turning, milling, and grinding to ensure that the final product meets the stringent standards set by manufacturers.

4. Heat Treatment

Heat treatment is applied to enhance the mechanical properties of the crankshaft. This process involves heating the component to specific temperatures and then cooling it down in a controlled manner to improve hardness and toughness.

5. Quality Control

Finally, quality control is an essential aspect of the manufacturing process. Each crankshaft is subjected to rigorous testing, including tensile testing, fatigue testing, and dimensional inspections, to ensure that it meets the required specifications.

The Importance of Quality in Crankshafts

The performance of a diesel engine is only as good as its crankshaft. High-quality crankshafts play an essential role in the overall performance and efficiency of the engine. Let’s examine why selecting reputable crankshafts manufacturers is crucial.

1. Optimization of Engine Efficiency

High-quality crankshafts can significantly improve engine efficiency. By providing a more precise fit and better durability, these crankshafts maximize power output while minimizing fuel consumption.

2. Longevity and Reliability

Choosing crankshafts from reputable manufacturers ensures that they are built to last. With rigorous testing and adherence to industry standards, manufacturers produce crankshafts that withstand the harsh conditions of diesel engine operation.

3. Reduced Maintenance Costs

Investing in quality crankshafts can lead to lower maintenance costs over time. Fewer breakdowns and a longer lifespan mean that businesses can save significantly in repairs and replacements.

Top Crankshafts Manufacturers in the Industry

With many companies vying for a top position in crankshaft manufacturing, knowing the leading players can help in making an informed decision.

- Client Diesel: Known for its robust and reliable crankshafts, Client Diesel stands out as a premier supplier in the diesel engine parts industry.

- CAT: Caterpillar Inc. manufactures high-performance crankshafts designed for their heavy machinery, renowned for durability and strength.

- John Deere: They offer reliable crankshafts that are extensively tested for performance, particularly in agricultural equipment.

- Mahle: A global leader in automotive components, Mahle produces crankshafts that focus on innovation and technological advances.

Future Trends in Crankshaft Manufacturing

As the industry evolves, crankshafts manufacturers must adapt to new challenges and opportunities. Here are some trends to watch out for:

1. Advanced Materials

Research into lightweight and stronger materials is ongoing. The use of alloys designed for specific applications could improve both efficiency and performance.

2. Automation and Digital Manufacturing

The integration of automation in manufacturing processes is set to enhance production rates and precision while reducing costs.

3. Sustainability Initiatives

With the push for sustainability in all industries, crankshaft manufacturers are exploring eco-friendly materials and processes to reduce their carbon footprint.

The Role of Innovation in Crankshaft Development

Innovation drives the manufacturing industry, particularly in enhancing engine performance and meeting engine regulations. Manufacturers need to invest in research and development to stay ahead of the curve.

1. 3D Printing of Crankshafts

While still in its infancy, 3D printing technology holds the potential to revolutionize crankshaft manufacturing. This method allows for complex geometries and weight reduction, catering to the demands of modern engines.

2. Simulation and Testing

Advanced simulation techniques are becoming integral in the design phase. Using software to model the performance of crankshafts can save time and resources in the long run.

Conclusion: The Importance of Choosing the Right Crankshaft Manufacturer

In summary, the crankshafts manufacturers play a pivotal role in the performance and reliability of diesel engines. With the right selection process, businesses can invest in quality components that enhance their operational efficiency, decrease costs, and ultimately drive success in the highly competitive automotive sector.

Whether you are looking for diesel engine parts or searching for spare parts suppliers, being informed about the best crankshaft options available is crucial for maintaining high standards in performance.

For more information on quality crankshafts and diesel engine parts, visit Client Diesel.